Medical Molecular Sieve Oxygen System

Specification:Oxygen concentration: 90% (v/v)Moisture content (dew point method): 0.07g/m³Carbon dioxide content: 0.01% (v/v)

Specification:Oxygen concentration: 90% (v/v)Moisture content (dew point method): 0.07g/m³Carbon dioxide content: 0.01% (v/v)

Specification:

Oxygen concentration: ≥90% (v/v)

Moisture content (dew point method): ≤0.07g/m³

Carbon dioxide content: ≤0.01% (v/v)

Solid material particle size: ≤10um

Solid matter content: ≤0.5mg/m³

Noise of oxygen generator: ≤85dB(A)

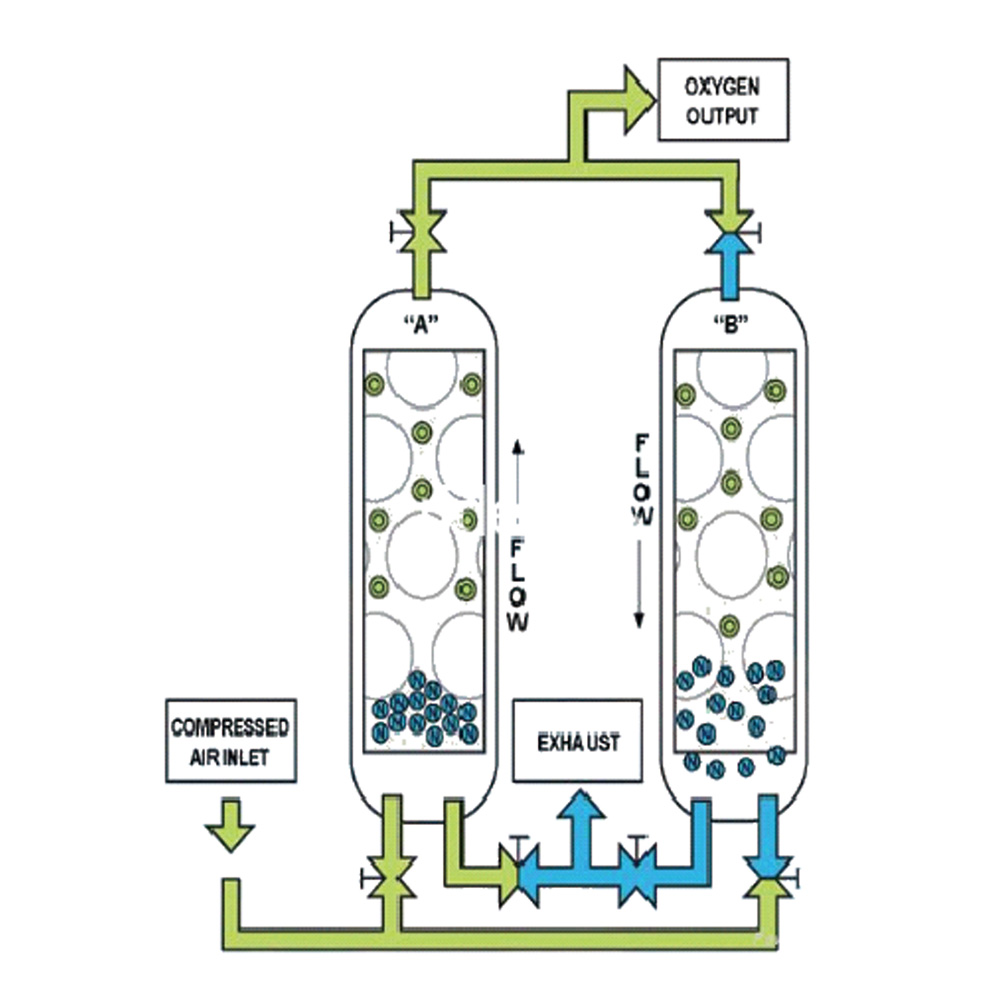

Principle of oxygen production:

PSA oxygen priduction uses molecular sieves as adsorbents and pressures adsorption (PSA) using ambient air as raw materials. Under normal temperature and low pressurize nitrogen in the air (adsorbent). The adsorption capacity increases, and the adsorption capacity increases, and the adsorption capacity of nitrogen in the iar decreases during decompression, forming a rapid cycle process of pressurized adsorption and decompression desorption, so that oxygen and nitrogen in the air can be separated, so that the oxygen purity of the produce oxygen can reach 93%±3% v/v or more.

Product advantages:

◆Unique combination valedesign.cetal combine the control valves to reduce system failure points, increase system stability, and make maintenance faster and more convenient;

◆Unique oxgen outpu control tecnology: The oygen output is controled by the flow rate, and the adsorption capacity of the system is controlled according to the unit flow rate. This technology can avoid the influence of third-party factors that are often affected by the traditional passing time control technology, and improve the stability of the system;

◆Data fedback control technology: input data feedback programming compied by Huiyu, real-time monitoring of system data changes self-detection of system soft fauts and self-diag-nosis and repair;

◆Remote monitoring technology: real-time monitoring and storage of various operating status and data of the oxygen production system, automatic data collection and transmission to the designated server, system administrators can check the system working status online at any location; and can control the oxygen production through the monitoring computer Start and stop th system and adjust the pressure and operating status of the equipment;

◆The oxygen production system has an automatic alarm function, which automaticlly alarms when the oxygen purity, pressure, and flow are abnormal, as well as machine failures and power failures.

Core value:

·Safety: real-time monitoring, automatic alarm, small amount of instant storage, low risks;

·Autonomy: using air as raw material, oxygen can be used on the spot, high quality and stable;

·Convenience: automatic system, liberating manpower, high safety.